When it comes to HVAC systems, the choice between flexible duct (flex duct) and hard duct (rigid duct) is a crucial decision that can impact the efficiency, cost, and performance of your system. At Will Air, LLC, we understand that each type of ductwork has its advantages and disadvantages, and the right choice depends on your specific needs. In this blog post, we will explore the differences between flex duct and hard duct, and help you determine which might be better for your application.

Understanding Flex Duct

Flex duct, also known as flexible ducting, is made from a metal wire coil covered with a flexible, durable plastic material and often insulated with fiberglass. It is highly versatile and can bend and twist in ways that rigid ductwork cannot. These are some of the main advantages of flex ducts:

- Ease of Installation: Flex duct is much easier and quicker to install compared to hard duct. Its flexibility allows it to be maneuvered around obstacles without the need for complex fittings.

- Cost-Effective: Generally, flex duct is less expensive than hard duct. The material costs are lower, and because it is easier to install, labor costs are also reduced.

- Versatility: Flex duct can be used in a variety of applications, including residential and commercial HVAC systems. Its flexibility makes it ideal for spaces where rigid ductwork would be difficult to install.

- Reduced Noise: Flex duct can absorb some of the noise generated by HVAC systems, leading to quieter operation.

While flex duct is durable, it is not as robust as hard duct and can be damaged more easily, especially if not installed properly. It also tends to have higher friction loss due to its ribbed interior surface, which can cause airflow restrictions if the duct is not stretched tight and straight. Additionally, flex ducts are more challenging to clean compared to hard ducts, as dust and debris can accumulate in the ridges, reducing efficiency over time.

Understanding Hard Duct

Hard duct, or rigid ductwork, is typically made from galvanized steel or aluminum. It consists of sections of straight ducts and fittings that are assembled to create a duct system. Here are some of the key advantages of hard duct:

- Durability: Hard duct is highly durable and can withstand harsh conditions. It is less likely to be damaged compared to flex duct, making it ideal for long-term use.

- Efficiency: Rigid ducts have a smooth interior surface, which results in lower friction loss and more efficient airflow. This can lead to better overall performance of the HVAC system.

- Easier to Clean: The smooth surface of hard duct makes it easier to clean and maintain. Regular cleaning can ensure the system operates efficiently and reduce the risk of indoor air quality issues.

- Fire Resistance: Hard duct is typically more fire-resistant than flex duct, providing an additional layer of safety in some applications.

Some of the disadvantages of hard duct include its installation complexity, as it is more labor-intensive and time-consuming, requiring precise measurements and fittings that can increase overall installation costs. Additionally, the materials and labor for hard duct installation are generally more expensive than those for flex duct, which can be a significant factor for budget-conscious projects. Hard duct also requires more space for installation, making it a limitation in tight or confined areas.

Which is Better?

The decision between flex duct and hard duct depends on several factors, including the specific requirements of your HVAC system, budget, and the physical space available for installation. Here are some considerations to help you make an informed choice:

- Application: Flex duct is often sufficient and cost-effective for residential applications. However, due to its durability and efficiency, hard duct may be preferred for commercial or industrial applications.

- Budget: If budget is a primary concern, flex duct can provide significant savings in both material and labor costs. However, consider the long-term costs associated with maintenance and potential airflow restrictions.

- Installation Environment: Flex duct offers the flexibility needed to navigate around obstacles in tight or complex spaces. In open or accessible spaces, hard duct can be installed more easily and may provide better performance.

- Air Quality and Efficiency: If maintaining high indoor air quality and system efficiency is a priority, hard duct’s smooth interior and ease of cleaning make it a better choice.

At Will Air LLC, we are committed to helping you find the best HVAC solutions for your needs. Whether you choose flex duct or hard duct, our team of experts is here to ensure your system is installed correctly and operates at peak efficiency. Contact us today to discuss your project and learn more about our HVAC services.

By understanding the pros and cons of both flex duct and hard duct, you can make an informed decision that best meets your HVAC needs. If you have any questions or need further assistance, feel free to reach out to us at Will Air, LLC. We’re here to help!

Hot Topics

Recent Posts

What Is Duct Cleaning and Why Do You Need It?

When was the last time you had your air ducts cleaned? If you can’t remember—or [...]

Top Maintenance Tips to Save Energy This Winter

As temperatures drop, homeowners and businesses rely heavily on their heating systems to stay comfortable. [...]

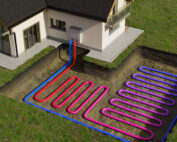

How Do Geothermal HVAC Systems Work?

Geothermal HVAC systems are gaining popularity as a sustainable alternative to traditional heating and cooling [...]

Maintain HVAC Efficiency During Extreme Weather

Extreme weather can challenge your HVAC system, pushing it to work harder than usual. Knowing [...]